Peptide synthesis is making a peptide bond between two amino acids. While there is no precise definition of a peptide, it often refers to chains of 30 to 50 amino acids that are flexible (with minimal secondary structure).

The capacity to generate peptide bonds to connect amino acids dates back more than a century. However, the first peptides, including oxytocin and insulin, were not produced for another 50 to 60 years, indicating the difficulty of chemically manufacturing chains of amino acids. In the last 50 years, developments in protein synthesis chemistry and methodologies have led to the widespread use of peptide synthesis in high-throughput biological research, product development, and drug discovery.

In addition to replicating peptides discovered in biological specimens, modern peptide synthesis techniques allow the generation of new peptides to maximize a desired biological response or other outcomes. In this piece, we will examine the fundamentals of peptide synthesis, the most widely used techniques of synthesis and purification, and what you need to know about each approach.

The Peptide Synthesis Process

A peptide comprises two or more amino acids connected by an amide bond to produce a chain of 2 and 70 amino acids in length. Peptides differ from proteins because they do not require folding for biological function. Peptides exist endogenously in plants and animals as peptide hormones, like angiotensin, LHRH, enkephalin, and toxins.

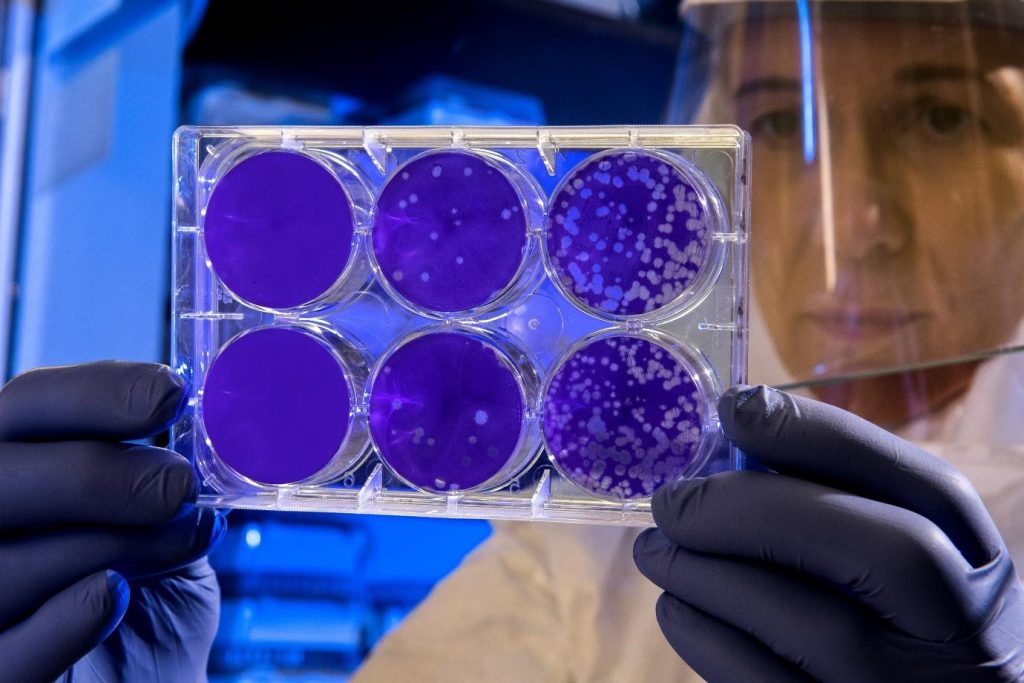

Peptides are chemically produced in either fluid or a solid phase. The method comprises the selective and directed formation of an amide bond between N-protected amino acids and an amino acid containing a free amino group and a protected carboxylic acid. Additionally, the carboxyl protecting group is connected to polymer support in solid-phase synthesis. The amino-protecting group of the dipeptide is eliminated after bond formation, and the next N-protected amino acid is coupled.

Application of synthetic peptides

In the 1950s and 1960s, the advent of peptide synthesis drove the development of several application areas in which synthetic peptides are utilized today. This includes making antibodies against pathogenic proteins with a specific epitope, studying how proteins work, and identifying and describing proteins. Synthetic peptides are also used to study the relationship between enzymes and their substrates in significant enzyme classes, including kinases and proteases, which are vital to proper cell signaling.

Groups of homologous synthetic peptides are frequently used in cell biology to examine the substrate recognition specificity and receptor binding of newly found enzymes. Like their natural counterparts, synthetic peptides may mimic the body’s peptides and be used to treat severe illnesses like cancer. In addition to their usage in vaccinations, biomaterials, and histology probes, antigens are employed extensively to create antibodies.

Synthetic peptides are also employed as reagents and standards in mass spectrometry-based procedures. They play a vital role in identifying, characterizing, and quantifying proteins using mass spectrometry, particularly those that act as early biomarkers of a health disorder.

Strategies for Peptide Synthesis

Scientists employed liquid-phase peptide synthesis when they first discovered how to synthesize peptides in vitro, and the technique is still widely used for large-scale synthesis. However, this process is time-consuming and labor-intensive because the product must be isolated from the reaction solution at each stage. In addition, this method needs an additional chemical group to shield the C-terminus of the initial amino acid. A benefit of liquid-phase synthesis is those side reactions are quickly discovered since the product is purified after each step. Furthermore, convergent synthesis can be undertaken, wherein distinct peptides are produced and coupled to build more extensive peptides.

Besides, solid-phase peptide synthesis is by far the most used method of peptide synthesis in use today. Instead of using a chemical group to protect the amino acid’s C terminus, the first amino acid’s C terminus is coupled to active solid support like polystyrene or polyacrylamide. During peptide synthesis, the resin serves a dual purpose: first, as a C-terminal protective group, and second, as a quick means of separating the developing peptide product from the various reaction mixtures. As with many other biological manufacturing techniques, peptide synthesizers are designed for high-throughput and automated peptide production.

Summing Up

Peptides are the most common natural protein and are quickly produced through chemical synthesis. Peptides are short chains of amino acids that can be used in many applications, including medicine, food additives, and biofuels. How do you make peptides? This article has answered that question and offered a comprehensive guide to peptide synthesis so that you can start experimenting with this field.

Peptides have a wide variety of uses. They can be used as antibiotics, drugs, biofuels, and cosmetic ingredients. For example, they can produce the renewable fuel ethanol or the non-toxic synthetic rubber-like substance known as luciferin-luciferase. Peptides are used to create bio-ink for printing biomaterials and are also used in biomedical research.

Synthetic peptides are biocompatible molecules that can be used in various applications. They can make biofuels, produce bio-ink for printing, and create antibiotics. Peptides are also a type of biopolymer compared to proteins. They have numerous advantages over proteins, and they are easy to produce. Therefore, synthetic peptides can be used as a replacement for proteins in many applications. If you are interested in peptides, this article is a must-read. With the help of this article, you will learn how to make peptides in chemical synthesis and why peptides are essential for biomolecules.